Search

Search

Search

Search

Integrating downhole diagnostics, real-time measurements, and live visualization so you can evaluate and validate fracture performance faster.

During stimulation, you want every stage to count, but do you know how effective your frac program is?

With core acreage diminishing and parent-child interference increasing, subsurface insight over what is taking place down hole has never been more important. However, many completions today are executed with high uncertainty. With limited subsurface insight, making improvements to optimize completions takes time, and typically a high well count.

To make every stage count, the SmartFleet® fracture monitoring system gives you real-time access to subsurface measurements, while providing live visualization of fracture performance across every stage.

This intelligence while fracturing helps you eliminate subsurface blind spots for more dynamic decision-making, so you can stop sacrificing value and start improving returns.

Advanced Fracture Monitoring

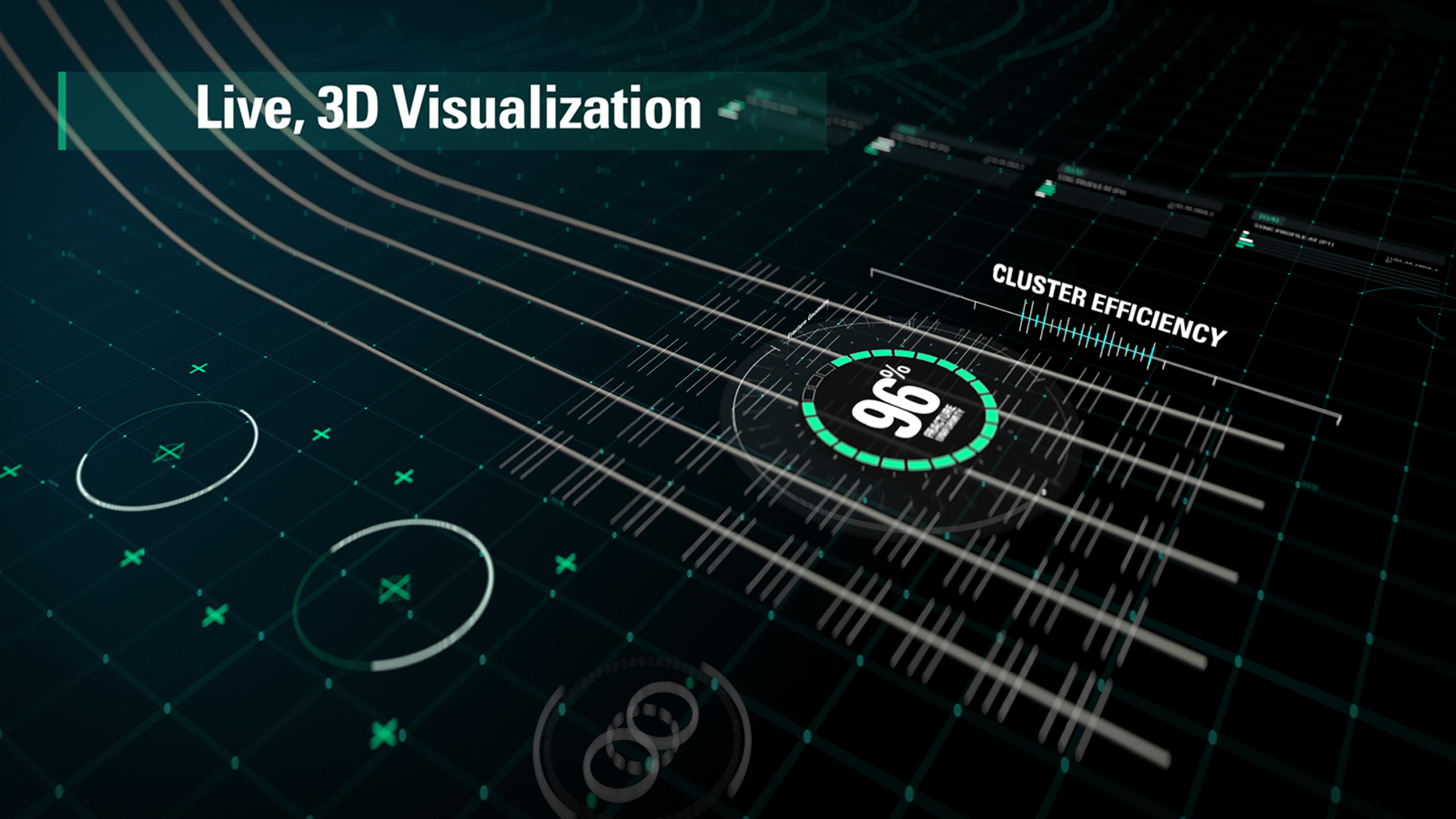

The SmartFleet system keeps you connected to the subsurface through real-time fracture measurements and live visualization, allowing you to validate fracture performance easier and faster.

Case Study

With SmartFleet, our customer was able to see, measure and act on the performance of their frac treatments in real time. This allowed them to quickly evaluate two different frac designs, understand their impact on drainage, maintain uniformity and optimize design changes to maximize asset value.

Learn HowTotal stages monitored

Total lbs of proppant pumped

Increase in average stage length

Through our latest scalable fiber optic monitoring services, SmartFleet interprets fracture performance by applying direct measurements of fluid distribution along the near wellbore, as well as interactions with offset wells.

SmartFleet provides real-time visibility of all critical subsurface measurements while pumping on location, and via a web-based software application that allows easy remote access. This live visualization software puts subsurface placement metrics and surface efficiency metrics at your fingertips.

For real-time action and stage to stage improvements, SmartFleet provides easy to interpret subsurface data and visuals to enable your team to evaluate fracture performance, improve fracture placement and manage well interactions.

mobile app

The SmartFleet app makes real-time insights more accessible, giving you access to fracture performance anytime, anywhere.