Search

Search

Search

Search

Team Contains Well in Emergency Situation Without Incurring Any Injuries

Download PDFMature Fields

Contain an emergency situation well blowout

South America

A well drilled in South America was planned for workover operations in order to access and evaluate new hydrocarbon resources. The well had been drilled in 1967 in a water depth of 90 feet (27 meters) to a total depth of 5,571 feet (1,698 meters).

During the workover operation from a single well platform, a blowout occurred with devastating consequences to the barge rig equipment and well platform. Consequently, due to the conflagration, the derrick collapsed and scattered debris across the platform.

The crew safely abandoned the barge rig while the operator implemented the emergency response plan, contacting Boots & Coots for assistance with the well control incident.

The Boots & Coots well control team was mobilized to the location to assess the situation and assist the operator on the response plan and operation. The team initially inspected and assessed the conditions of the barge and well. Gas was flowing into the lake bed and then to the water surface where it had caught fire.

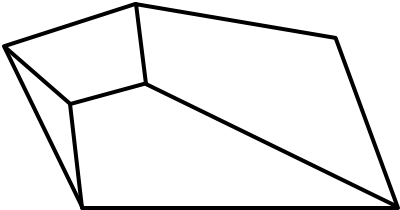

The underwater survey showed that the well platform, casing, and tubing strings had been bent and collapsed on the well (as illustrated below), increasing the challenges. Additional debris littered the lake bed surrounding the wellhead, which restricted access and the ability to clearly monitor the wellhead. Furthermore, the turbulence from the gas flow through the debris disturbed silt and clay on the lake bed and clouded the visibility around the well.

Debris removal was performed with the help of divers, who were able to recover part of the collapsed casing during the operation. While monitoring the well condition and gas flow behavior, plans were updated periodically to mitigate risks and ensure overall operational safety. Fortunately, the flow from the well ceased during early stages of the debris cleanup operation, which reduced risks tremendously.

Subsequently, all the debris from the vicinity of the well was removed safely and without incurring any injuries.

After removing the debris, a longitudinal crack was observed on the production casing at the base of the lake bed. At this point, the integrity of the production casing for any source control operation was thrown into question.

The well source control procedure required installing a capping stack on the well, so a decision was made to dredge sufficient depths of the lake bed in order to access competent production casing for the capping operation. A total of 18 feet (5.5 meters) of the lake bed was dredged with special turbine equipment to uncover a sufficient length of competent production casing.

Boots & Coots designed a modified surface capping stack, based on the available 11-inch x 10-meter (33-foot) blowout preventer’s (BOP’s) surface equipment. The compromised section of the casing was cut to expose a sufficient length of competent casing for the subsea capping operation. Boots & Coots specialists oversaw the capping operation and safely conducted a successful landing to secure the well.