Search

Search

Search

Search

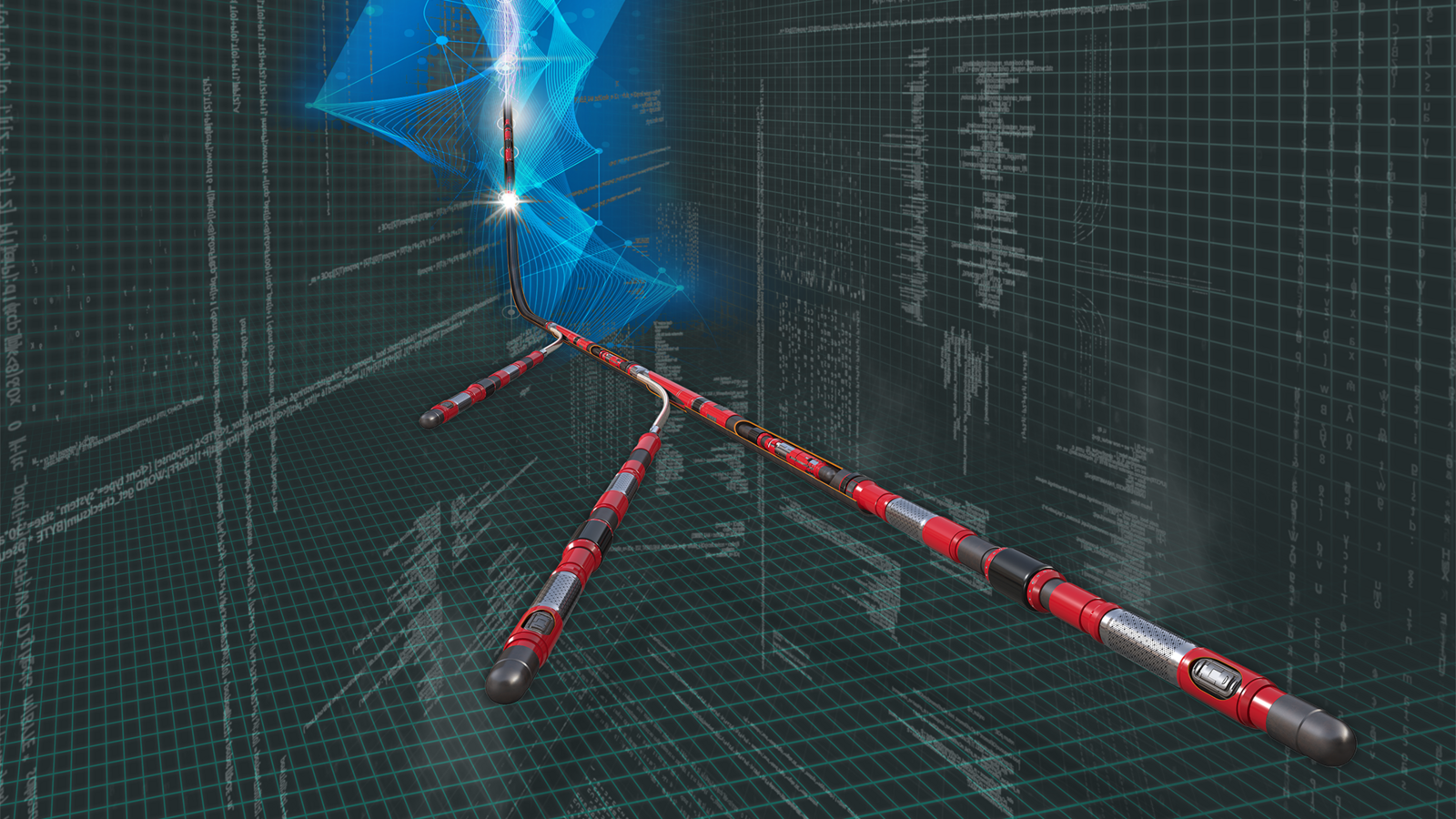

Real-time completion orientation using the workstring orientation tool maintains through-bore access and minimizes rig floor handling

Download PDFMature Fields

Orientate and land multilateral completion assemblies

North Sea

Orientate and land multilateral completion assemblies, while maintaining through-bore access for liner hanger setting operations

Deploy the WOT, a retrievable MWD service tool based on the COT, which uses the wallimounted telemetry system

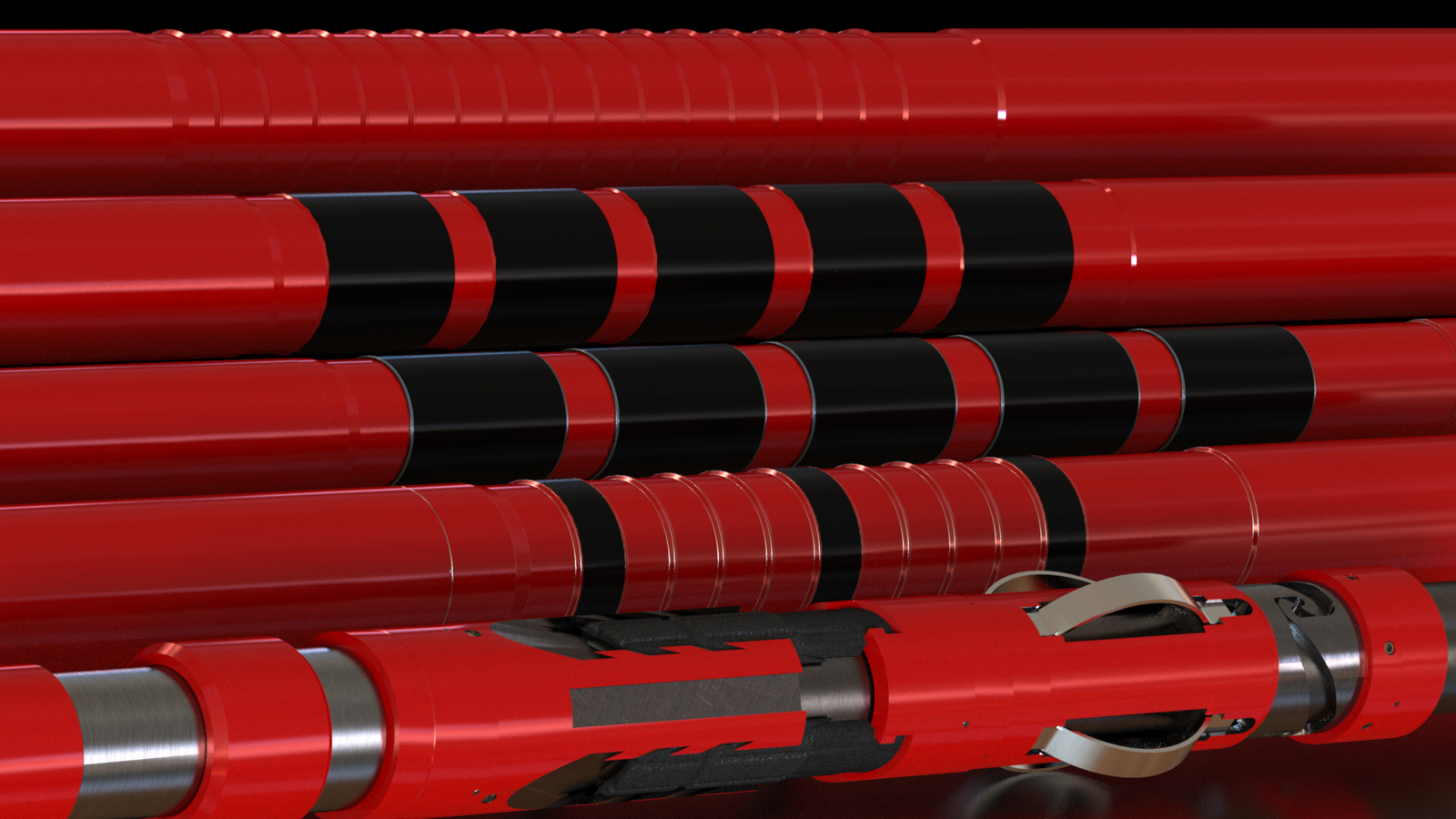

Since 2001, Halliburton has been installing the FlexRite® Level 5 multilateral junction system within the Norwegian North Sea. Initially, the pre-milled windows were deployed using traditional measurement while drilling (MWD) in combination with an inner string and key sub. However, in 2013, the first Casing Orientation Tool (COT) was successfully run, resulting in a significant time savings by eliminating the inner string makeup and breakout and subsequently becoming the standard method of deploying pre-milled windows within the sector.

Despite the success of the COT, multilateral junction completion activities were still tied into traditional MWD as supplied by the directional drilling vendor, resulting in additional lines of communication during the job-planning process. Furthermore, online inner string makeup and high-side offset confirmation increases overall wellbore construction time and poses additional health, safety and environment (HSE) risk by requiring personnel be present within the red zone. In response to this, and building on the success of the COT, the Workstring Orientation Tool (WOT) was developed.

Using traditional MWD equipment for multilateral completions requires some compromise. While running the junction, the requirement to make up the MWD hang-off collar below the liner hanger necessitates rig floor activity, placing personnel within the red zone while components are made up and the tool offset is recorded for accurate high-side placement.

Additionally, because flow-rate requirements vary for multilateral equipment used in each operations phase, multiple MWD tool sizes are necessary during junction construction. The positive pulser used during traditional MWD requires placement inline with the tubing flow, causing a restriction and precluding the use of ball drop activities when run above the service tool. This can result in the loss of the contingency release mechanism during completion deflector deployment. Finally, the requirement to run float valves below the traditional MWD system presents potential debris tolerance issues, which could be problematic during operations that require lost circulation material (LCM) displacement.

To validate the COT design update, the redesigned components were run successfully using the WOT platform during field trials in 2014. Based on the positive results, the tool was put forward for technical qualification for field use with a Norwegian operator’s multilateral wells and first run in 2017. The WOT addresses the issues associated with traditional MWD; the 3-inch through-bore allows it to be run above liner hanger and deflector setting tools without sacrificing the contingency setting option. With no requirement to run a float valve below, no debris tolerance issues exist, removing the blocking potential through the tool ID. The significantly lower operating flow rates (250-LPM minimum), help eliminate the need to run different MWD tools over subsequent operation phases, resulting in additional time savings and reducing equipment requirements for multilateral junction construction.

Critically, the WOT eliminates the requirement to run MWD equipment on an inner string below the liner hanger/ packer setting tool, which is used in junction deployment. This minimizes the need for personnel in the red zone during the equipment makeup procedure and results in a direct risk reduction.

TAML level 5 of it's kind

WOT successfully deployed in North Sea

risks reduced

Since its initial field trial, the WOT has been deployed successfully 50 times within the Norwegian North Sea. Compared to the inner string makeup activities required with MWD for junction deployment, the WOT provides significant time savings by reducing string makeup requirements. Additionally, the tool’s sufficiently low operating flow rates are compatible with the complete suite of multilateral completion running tools, thus reducing overall equipment requirements. These features directly reduce the HSE risk associated with personnel on the rig floor.

As the case history has progressed, design updates have increased the potential scope of the tool — with the most recent generation designed for use in re-entry applications when used in conjunction with the XtremeGrip® multilateral anchor system.

MULTILATERAL SYSTEMS

The multilateral system is designed for new well applications, providing significant additional per-well reservoir exposure which potentially reduces development costs and times and greatly improves field economics.

View Data Sheet

Achieve greater profitability and a higher return on investment with innovative multilateral technology.

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications.